- 3D-Modeling

- 3D-Print

- Bachelor

- Cologne

- Digital Fabrication

- Milan

Through the integration of digital fabrication tools in actual design and production processes, the boundaries between design development and production become increasingly blurred. In contrast to a concept of hierarchical design development in this environment the design development process is driven by the process of making: thinking by making. After the era of industrial production, the possibilities created by computer-aided design and manufacturing revive some fundamental principles of traditional crafts and inevitably lead to new design aesthetics. The course explores this potential through the processing of digital designs into physical objects.

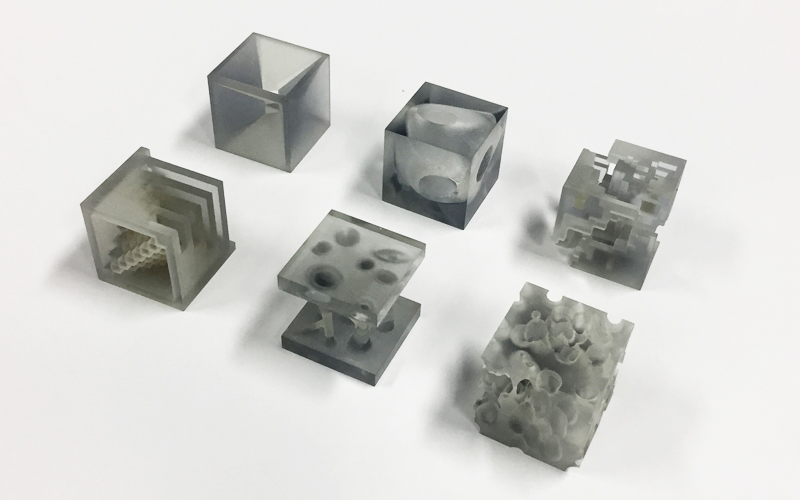

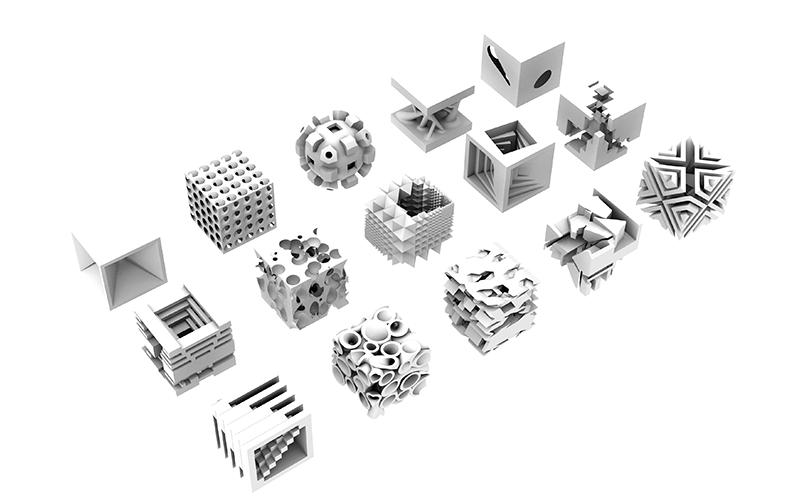

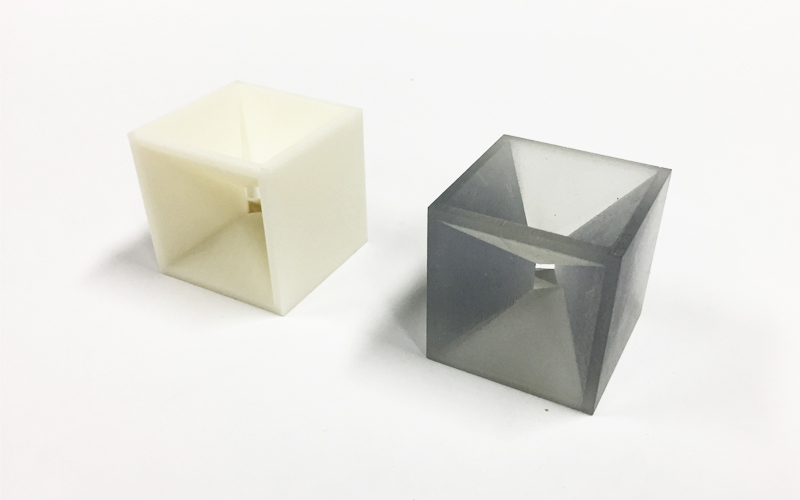

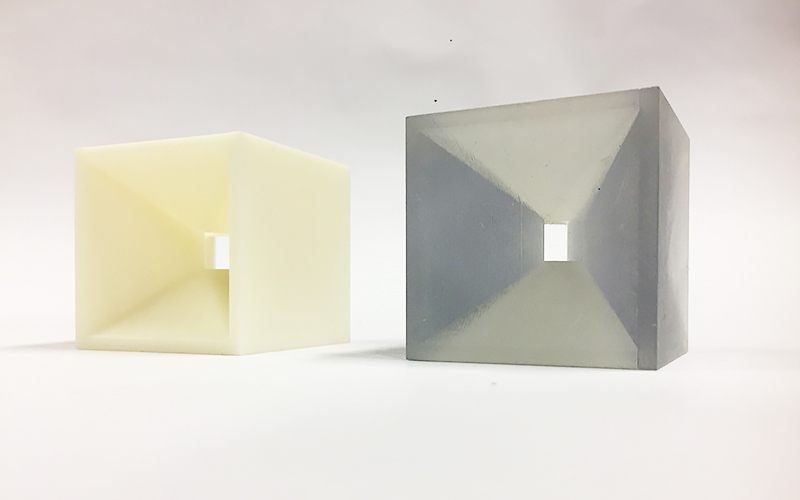

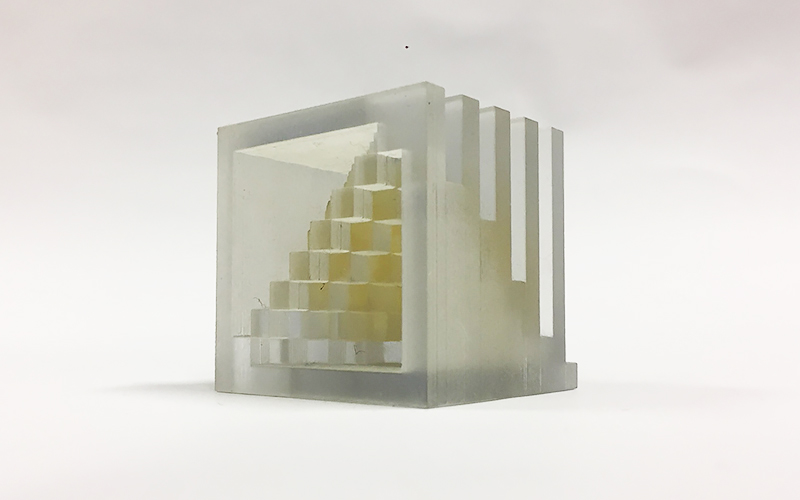

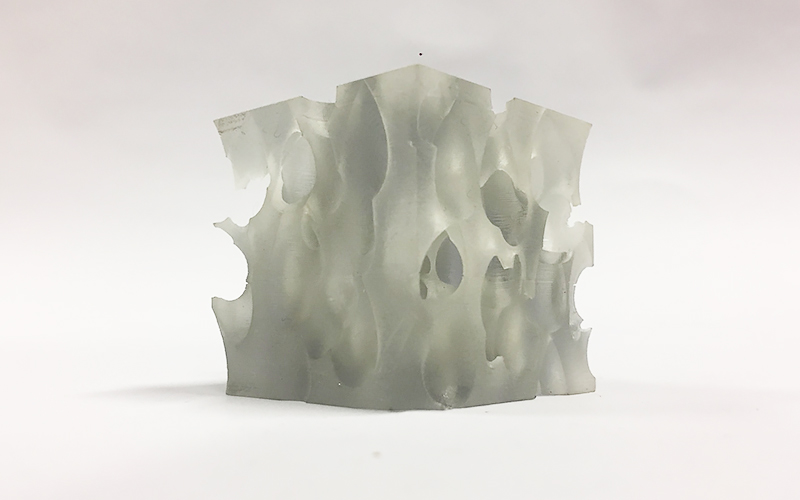

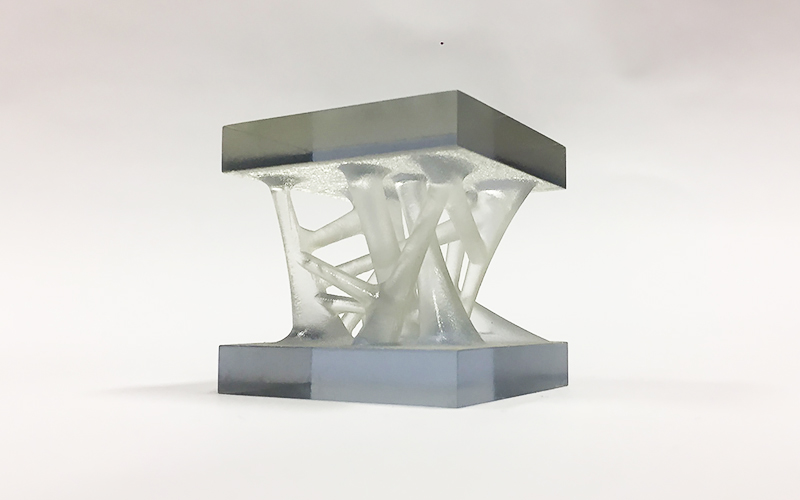

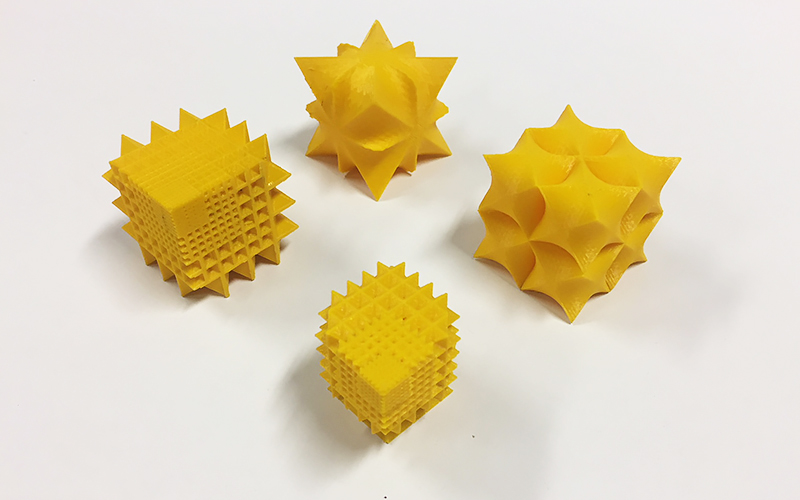

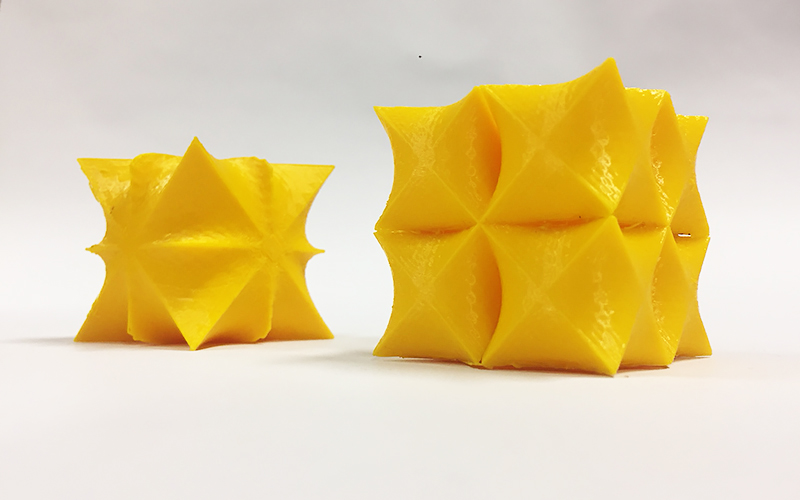

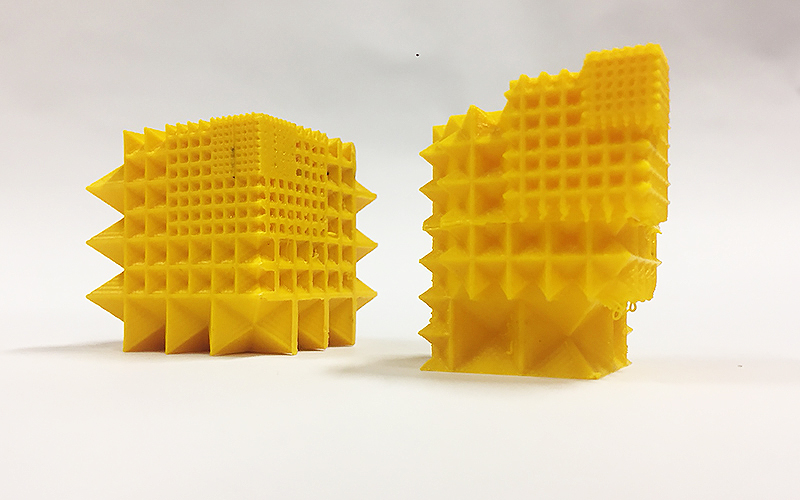

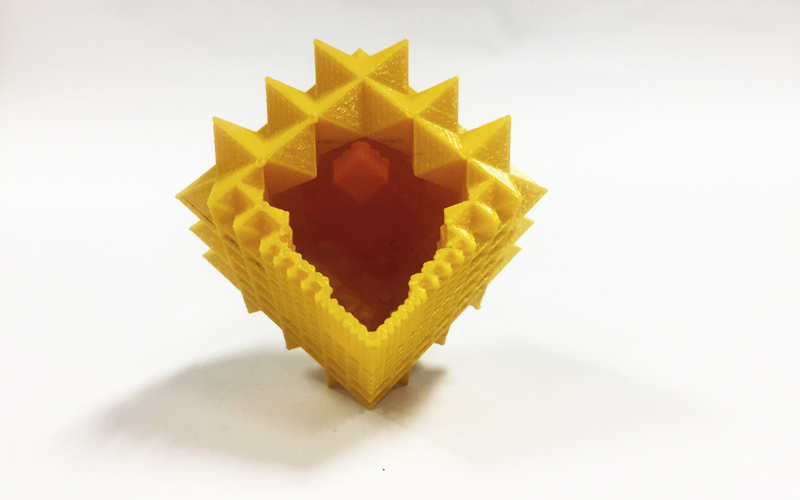

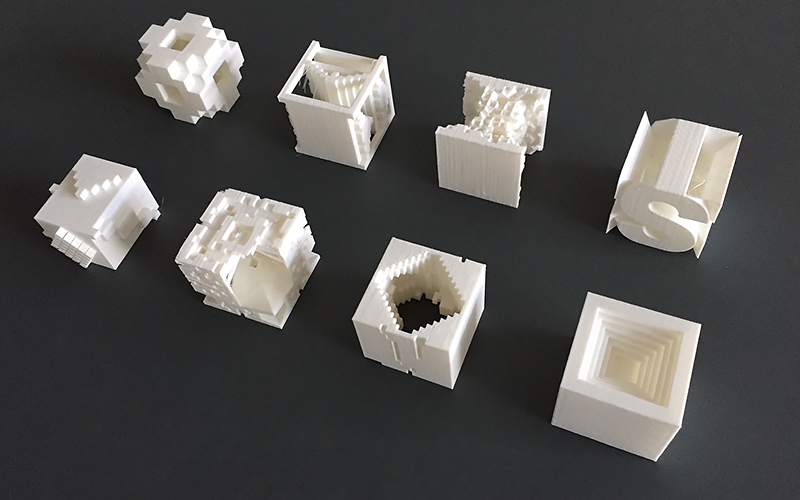

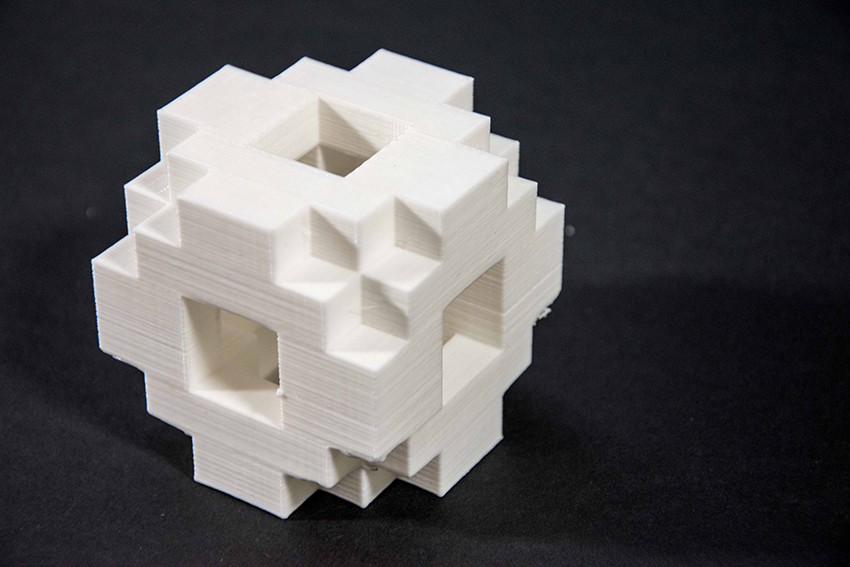

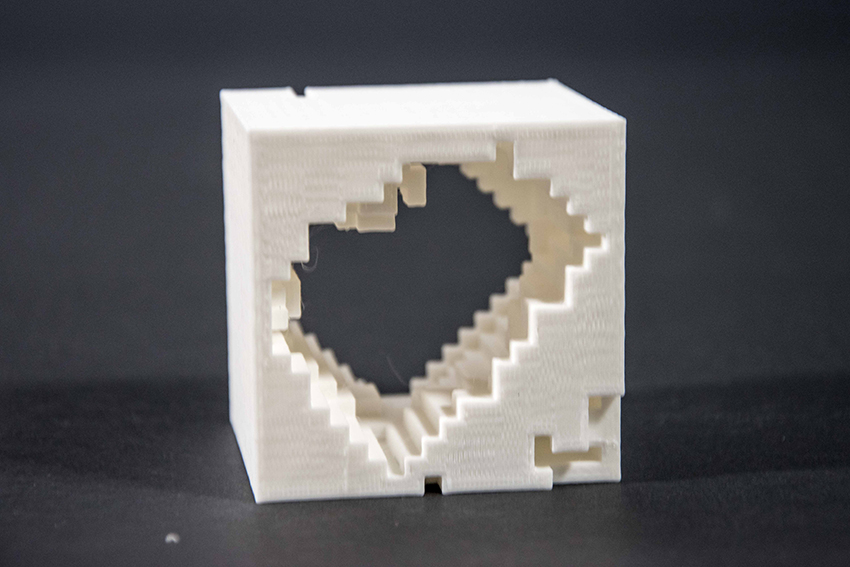

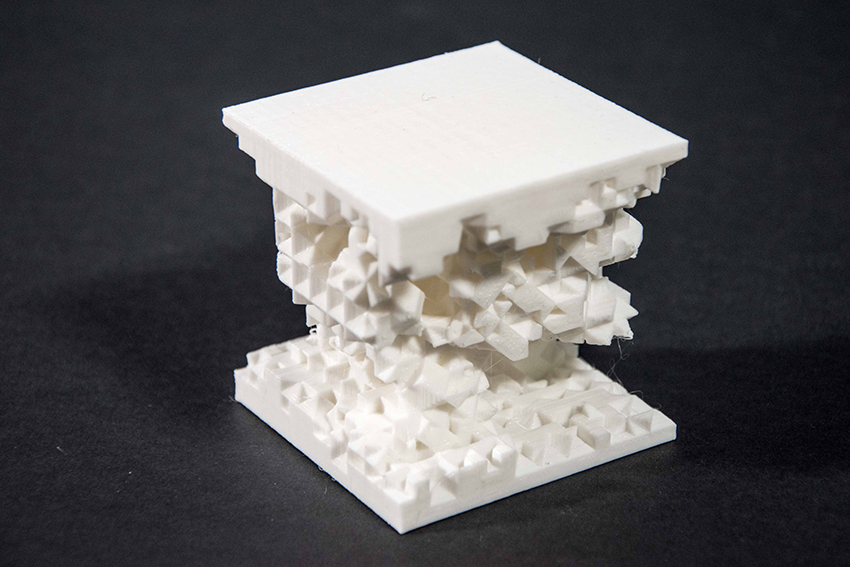

3D-printers allow for the production of complex models, which are (almost) impossible to materialize with traditional fabrication techniques. The aim of this first exercise of the course was to develop an architectural sculpture, generated by a design approach based on the subtraction of constructive solid geometries from a pre-defined cube. The main constraint of the task was that the volume of the final object had to be exactly 50% of the starting volume, neither more nor less. A second constraint was imposed by the modelling technique, which was based on Boolean operations.

CREDITS

Daniel Polo, Giada Bevilacqua, He Yuan, Cindy Hens, Pietro Ciurlo, Olivia Daw, Andrea Colombo, Andrea Ferrerio, Maria Giardino, Mikael Svenson, Matteo Cavaglià, Sabrina Sgaramella, Daniel Favaro, Emiliano Berni.

Marco Hemmerling, Alessio Mazzucchi

Politecnico di Milano

André Classen, Simon Berke, Elena Lang, Johann Hoerniss, Janik Lügtenaar, Patrick Jantzen, Marie-Theres Ley, Natalie Marek, Tom de Silva

Marco Hemmerling, Jens Böke

Faculty of Architecture, Cologne University of Applied Sciences